Jim Leach Pacific Tiger Club

published in the January 1997 Rootes Review

When our cars were designed and built, no one at Rootes or Jensen could have imagined so many Sunbeam Tigers would have survived 30+ years and that they would develop such a strong following of enthusiasts? Many parts and components have been re-manufactured, and restored Tigers are in fact better cars today than they were when they left the showroom.

One item on most Tigers that has not received attention is the steering column … a fairly important part!

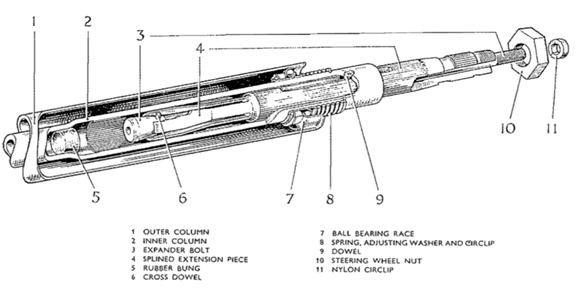

Column Assembly

The bearings (in the top and bottom) are unique and, at this time, are unavailable and irreplaceable; they vaguely resemble newspaper cart wheel bearings. Two types of column assemblies were used on Tigers and both types have design problems. To identify the style of unit you have on your car, look at the steering knuckle end. Both types share the same outer tube, bearings, and springs. However, the center shaft is different at the bottom.

The early (Type 1) unit uses snap rings top and bottom to retain the small parts and has a variety of shim washers to set bearing pre-load. The exposed lower portion of the center shaft is tapered and smooth. The later (Type 2) unit uses the same small parts at the top, including a snap ring and shim washers to retain the center shaft, but it has a threaded lower portion that is double-nutted and it uses different small parts internally.

The Type 1 unit does not incorporate any form of seal to keep grease inside and road dirt outside of the lower bearing.

Column Rebuild

I have rebuilt over 20 of these and the lower bearings on every one have been full of sand and powdered sand; the bearings work as a small ball mill, something like a pharmacist’s mortar and pestle. A few owners have pushed grease into the bearing (which may or may not be wise) and the sandy paste works like valve grinding compound on the bearing surfaces. An average of four out of five lower bearings have light to moderate damage to the races, ultimately resulting in flaking and chipping of the hardened raceways. One out of four has some degree of rust damage and I often see pits in the chrome surface of the balls.

The Type 2 unit was redesigned and “improved” and has a felt seal outboard of the lower bearing behind the retaining nuts. The bearing is usually free from road dirt however the dried grease does not lubricate or protect the bearing from water damage. Unfortunately, the felt seal acts like a sponge and holds moisture. I have rebuilt 10 of these and 9 had moderate to extreme rust damage to the bearing and small parts and to their center shafts. Three bearings were not rebuildable and two units had to be disassembled with a die grinder. Replacement parts were then manufactured to complete the rebuilds.

The upper bearings in both types of columns rarely rust, although 30+ year old grease has turned to clay and provides no lubrication at all. One in every eight center shafts have shown damage from seized bearings; the shafts have been scuffed by the bearing center. The splined telescoping adjuster is a very clever gadget that suffers from the same petrified grease as the bearings, and this is the main reason steering wheel height is difficult or impossible to achieve. This unit can be damaged by repeatedly telescoping the column and banging it at the upper and lower travel limits.

Care must be taken whenever a Tiger or Alpine steering wheel is removed. If it does not come off easily, a gear/steering wheel puller should be used. I do not recommend attaching the puller to the three captive nuts in the center of the (original) wheel. There is a tendency for the ornamental plastic center of the wheel to tear away from the steel structure. I prefer to drill two new holes completely through the plastic/steel/plastic center (on the centerline of the crossbars) adjacent to the brass captive nuts and pass long bolts through them from (or to) the back side. Use the largest washers that will fit to distribute the force applied by the puller. Be certain to leave the main nut loose on the end of the adjuster to protect the threads; they are an unusual size and thread count and because this piece is tubular, the end can mushroom or flare over the end. When reassembled, the holes drilled in the wheel will be completely hidden and you will avoid making a three piece steering wheel.

Columns that have been altered or damaged can usually be repaired. Bent column tubes and center shafts can be straightened and the telescopic splined tube or locking pin can be replaced. Unfortunately, it may require an Alpine steering column for parts. I am interested in purchasing Alpine steering columns for donor parts and Tiger columns to become exchange units. If you have one available, please contact me! A Tiger owner somewhere will appreciate it. My complete Tiger column restoration service includes: disassembly and thorough cleaning of all parts, and a close inspection. The bearing races are lathe polished (as smooth as possible), and reassembled with new chrome steel balls, and with modern high-temperature grease. I have re-manufactured new felt spacer/grease reservoirs that are an integral part of the bearings and install these in each unit. Type 2 columns receive a new outer felt seal saturated with silicone grease to block water entry and, if requested, I can install PVC rubber bellows or gaiter on Type I columns to completely seal the bearing from the elements. The remaining small parts are sandblasted, washed, and painted with Hammerite smooth black finish. The column tube is also sandblasted and washed and is powder coated in your choice of a high gloss or satin finish black.

The brake and clutch master cylinders are directly above the column and unlike paint, powder coating in impervious to brake fluid. The cost to restore a column is currently running between $160 and $200, depending on the hours invested. Turnaround time is variable, based on my having several column tubes ready (at the same time) to distribute the powder coating expense.

Comments (2)

do you still rebuild Tiger steering columns? If you do, please contact me as I could use some help, Thanks, hope things are going well for you. Cliff Morgan

Cliff,

I’d suggest you post a question on the TEAE forum. Someone on the forum may be able to point you in the right direction. Good luck!