by Fred Baum in the May and June 2006 RootesReview:

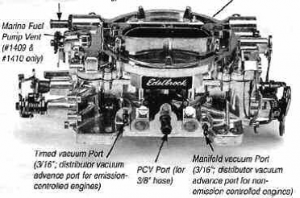

About ten years ago I gave up on my Holley 4-barrel carburetor and purchased an Edelbrock four-barrel. The Edelbrock Performer Series carburetors are a redesigned Carter unit that gives near electronic fuel injection economy while maintaining wide open throttle performance. This design is very reliable. They start at 500 CFM and go to 800 CFM. Manual or electric choke options are available. The #1409 600 CFM and #1410 750 CFM units are marine applications. The 800 CFM units are for high performance street/light strip use.

The carb part number is stamped on the pad at the front of the carb after the four digit manufacturing code number.

The correct idle mixture is essential for smooth idling as well as to create a seamless transition to open throttle operation. Setting the idle mixture is done by turning two screws located at the front of the carb. Turning these screws out gives a rich mix, in yields a lean mix. The optimum setting is the leanest possible ratio to give maximum vacuum pressure at idle RPM.

The correct idle mixture is essential for smooth idling as well as to create a seamless transition to open throttle operation. Setting the idle mixture is done by turning two screws located at the front of the carb. Turning these screws out gives a rich mix, in yields a lean mix. The optimum setting is the leanest possible ratio to give maximum vacuum pressure at idle RPM.

A vacuum gauge can be used to properly set the carb idle speed, or it can be done with a tachometer, or both. I have mounted a vacuum gauge in my Tiger in the hole that used to house the clock so I can check the vacuum at a glance. I have had the model #1404 installed in my car (MKI, stock 260 motor) for 10 years and have never had to make adjustments. It could probably use a rebuild at this point, since all the components are 10 years old, and the car sits for a good part of the year. The 1404 is a 500 CFM manual choke, non-EGR model recommended for small cubic inch stock motors; small is 400 cubic inch or lower. Above 400 cubic inches you should use a dual quad set-up.

Go to www.edelbrock.com for a chart of carburetor applications and specifications.

Go to www.edelbrock.com for a chart of carburetor applications and specifications.

The carburetor comes with primary metering jets of 0.086”, secondary jets of 0.095”; metering rods are 0.065” x 0.052”.

To set the proper idle mixture adjustment, follow these directions:

Set the idle mixture screws two turns out from bottom as a starting point. This is rich, but will give a baseline for further adjustments. Remember, we are looking for the best vacuum reading possible at a set idle speed.

- Fully warm the motor so the choke is fully open.

- Install the air cleaner.

- Set the desired idle speed with the idle speed screw.

- Adjust the idle mixture screw on one side to get the maximum possible RPM or highest vacuum reading. Do not go rich beyond the maximum speed.

- If the above procedure changed the idle speed more than 40 RPM, readjust the idle speed.

- Adjust the screw opposite the side just done. Obtain maximum speed or vacuum reading for this screw.

- Reset the idle speed.

- Carefully trim each idle mixture screw to again get the maximum idle speed or vacuum reading.

- Go leaner just enough to get a 20 RPM drop in speed.

- Reset the speed to the desired RPM.

This is a lean-best idle set. Settings richer than this will not improve idle quality or performance. They could, however, cause higher hydrocarbon emissions and tend to foul spark plugs.

Calibration kits are available to change the metering jets and rods to suit different operating conditions or engine combinations. All the kits include one pair of metering rod retaining springs, five pair of step-up springs, and a specified number of rod pairs and jet pairs, depending on the size carburetor being used.

Advantages

Last month I wrote about the set-up and tuning of the Edelbrock carburetor. One item I neglected was the advantages an Edelbrock has over its competition.

Several characteristics make Edelbrock carburetors outstanding street performers. They use metering rods to transition between circuits, and are unaffected by engine backfires. This means there are no power valves to blow out; the rods can be changed in seconds, without carburetor removal or fuel draining.

They have the unique ability to “hold a tune”, so once they’re tuned, they stay tuned. This means that compared to other carburetors the performance remains consistent and the calibration stays unchanged. The all-aluminum body is compatible with gasohol and blended fuels, and features a two piece body that resists warping.

The tub-type bowls and rear-pivot floats all contribute to a carburetor that is reliable, user-friendly and is easily tuned for trouble-free operation.

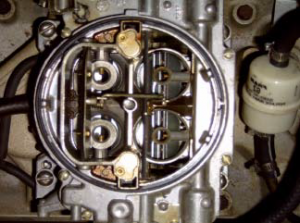

I removed the secondary counterweights and drilled 3/8” diameter holes in them. The secondary’s open faster, meaning they open with less vacuum drop than with the stock set-up. I find the car accelerates somewhat faster once the secondary’s kick in. There is no bog under heavy acceleration from low RPMs.

As I mentioned last month, I have not touched the set-up on my Edelbrock since installing it ten years ago.

Comments (1)

Great read! I recall the Carter AFB’s I utilized on my ’62 409 Chevy engine in my ’58 Impala and the simple adjustments I could make with the metering rods…

Still have a couple of the “E” Series someplace around the shop……

DanR

P.S. Now maybe I’ll look for a “New carb” in the 390 area for my 2.8 V6 in my Sunbeam Alpine