…And it worked for me!

by Ron Rogers

I am about to divulge a secret that has been invaluable for making my car win races for the last six years. Are you ready for this one? I know that I have maximum braking power. This fact not only helps the car perform better, but also helps me be a little more daring on those “deep comers.” I’ll explain why you’re not developing full potential and more importantly, how you can, no matter how much work you’ve done on your brake system.

In the beginning, all Sunbeams were created equal. That is, equal tires front and rear, with the same width, same height and same compound. The brakes were also calibrated by the factory to stop with the front wheels locking up before the rear wheels. This is important because it prevents your rear end from passing you in a hard brake situation.

So what’s the problem? Unless your car has original tires (and even if they do) you can probably lock your front wheels long before your rears, if at all. What this all means is that your brake system is not fully balanced for maximum braking. If your car has been changed since production with different size tires front and/or rear, traction bars to prevent spring wrap-up under hard braking, altered ride height in any way, or altered weight distribution front/rear, you really are asking for it.

But wait! No need to send your car to Ralph Nader and take the bus. A simple and extremely effective solution is at hand. All we want to do is shift more of the braking load to the rear wheels. Other than changing lining, compound and/or sizes, the most effective solution is an adjustable brake-proportioning valve. The best one that I know of is made by Kelsey-Hayes and sold through Ford and Chevy dealers. The Ford part number is C5ZZ 2BO91 B and the Chevy number is 3878944. The valve will have to be installed on the brake line that you want to reduce pressure on; that is, the front brake line.

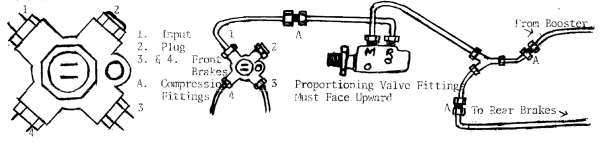

To install the proportional valve you will need the valve, a three-way tee block, three or four compression fitting connectors, five double flare ends and fittings, one brass plug, and three or four feet of steel brake line. I’ll leave the placement of the valve and tee block up to you, but you must put the parts on in the correct way. Remove the line from the servo to factory four-way tee. You will have to cut the ends off this line about four to eight inches from the fittings. The three-way tee and valve must be installed between the servo and factory four-way tee. The rear brake line must be removed from the factory four-way tee, the hole plugged and the line connected to the remaining hole in the three-way tee. Here’s how it looks:

Now comes the good part, the set up. First, bleed the front brakes to remove air from the valve. Really stand hard on the brake to make sure there are no leaks anywhere. Then, go to an empty parking lot with wrenches for adjusting the valve, a roll of masking tape, and a friend. Place a strip of tape every 90 degrees on the sidewalls of the front and rear tire on one side of the car. With the valve in the “full in” position, start doing panic stops from about 20 to 30 mph while your friend watches the tires. He’ll have no trouble telling which wheel is locking up first. Gradually back out on the adjuster until the rears lock first; then back in slowly until the fronts lock up just before the rears. Tighten the lock and you’re home. When you can see exactly what your brakes are doing, there is no doubt on how they’re working. If you change your tires or brake linings or suspension, no problem, just readjust! You’ll know you’re at maximum. It worked for me.