by Dave Spiwak (June 1994) in the January 2002 RootesReview:

Having spent fifteen summers in a black MkI Tiger running at 210 degrees, I finally decided that a rolling sauna was not my idea of a sports car. Here are some thoughts on reducing engine heat. My car now runs at 185 degrees.

For the basic cures for engine overheating, see pages B1 and B2 of the Sunbeam Survivor. Number one cure is the installation of the “Indiana Core” available from North Side Radiator. Call Barry Schonberger for information.

Editors note (in original article): other options that have been recommended are;

A copper core with four parallel rows of 5/16 inch tubes on 3/8 inch centers, with a serpentine fin density of 14 fins/per inch

A copper core with three parallel rows of 1/2 inch tubes on 7/16 inch centers, with a serpentine fin density of 18 fins/per inch.

The aluminum Griffin 1-1/2 inch thick serpentine core from Tiger Auto

If you are installing steel headers, wrap them with header insulation (J. C. Whitney or any speed shop). This blows engine heat out the exhaust instead of into the engine compartment.

I mounted a quality auxiliary radiator in front of my existing radiator. Various sizes are available from Earl’s Performance Products, Carson, CA 90745. Mine is 10″ x 11″, #43410.

I then installed an old heater core in the right wheel well. Due to the air turbulence around the front wheels, this does not offer great heat transfer, but it is cheap ($15.00) and increases the capacity of the cooling system. Any junkyard heater core will do (I chose a Ford, of course). My local garage made a bracket of steel for a few dollars. You will have to drill a hole in your fender for passage of the hoses, but the 1″ x 2-1/2″ hole is nothing radical–easily patched later if desired.

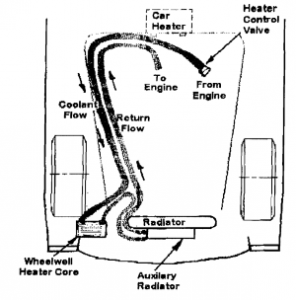

Here is how this “unorthodox” setup works. When spring arrives, drain your cooling system and disconnect the hoses to your heater. Using 2″ long pieces of 1/2″ copper tubing as connectors, route your existing heater hose (the one that supplies hot water to the heater) to the new heater hose and run it through the fender hole to the heater core in the wheel well. Be sure to use hose clamps on all connections. Run another hose from the other side of the heater core (we’re still in the wheel well) back through the fender hole and through the hole behind the horn on the passenger side. This hose gets connected to the TOP intake on the auxiliary radiator. Another hose goes from the bottom of the auxiliary radiator back through the horn hole and connects to the original heater hose that returns to the engine. Now refill the cooling system and bleed the air.

Editors Note (in original article): Would the auxiliary radiator detract from the main radiator’s ability to work by blocking off some air flow? Although this can only be determined by actually testing it, my intuitive feelings is that since a lot of the Tiger cooling problem is air restriction behind the radiator the obstruction in front would not add that much to the total and therefore the extra radiator would help.

This may sound confusing, but the drawing shows how it works. Very little mechanical ability is needed for this job. The result is as follows: When the heater control is set to the “car” setting, hot water from the engine is routed to the auxiliary heater core in the wheel well where some heat is radiated away. Water continues from the heater core to the auxiliary radiator in front of the stock radiator, where more heat is dumped. Water moves from the bottom of the auxiliary radiator to the original heater hose where it returns to the engine to pick up more heat. The new heater core, hoses and radiator add 1 1/2 quarts to the capacity of your cooling system.

In winter, I reconnect the car’s heater core and isolate the other lines by plugging them with pieces of 1/2″ copper tubing with copper caps soldered on one end (these are standard plumbing items). Use hose clamps to hold the tubes in the hoses.

I offer a final touch that differs from the very popular practice of blocking off the holes behind the horns. I suggest attaching flaps of inner-tube rubber (or rubber roofing material) at the top of each horn hole so the flaps hang down and cover the hole while you are stopped in traffic, but will lift up at speed when air can rush through and help cool your exhaust manifold or headers. Use metal screws or pop rivets at the top of each flap. A problem with Tigers is that when sitting in traffic, hot air is drawn through the horn holes from the engine compartment and then through the front of the radiator thereby re-circulating the same superheated air over and over. Be sure to install the flaps on the engine compartment side and make them big enough that they won’t flap through the holes!

Editors note (in original article): I do not recommend this idea. The horn holes should always be blocked off so that all air that passes through the engine compartment passes through the radiator.

Where bends are tight enough to crimp the hoses, make 90 degree fittings using cheap copper elbows and sections of 1/2″ tubing. Use wire ties to keep hoses away from moving belts. This setup results in a non-stock and somewhat cluttered appearance under the hood, but it does help lower your temperature.

Another idea I believe is worth trying is the addition of a 5″ x 16″ sheet steel spoiler mounted on the two existing holes on the front valance. If painted to match the body, it would not be very visible. It would serve a dual purpose. It should direct more cooling air through the radiator and also allow hot air to be pushed out of the engine compartment faster due to reduced pressure under the car. I have not yet tried this, but it is a very inexpensive and easy project to try. Use sheet steel plate and bend to an angle of about forty degrees.

Passenger Compartment Cooling:

Now that you have reduced your engine temperature, let’s work on cooling the inside of the car. Those of us with MkI Tigers have a real problem with heat transferred through the firewall due to the lack of under-dash vents.

Start by removing the front carpets. Open your hood to allow either sunlight or artificial light into the engine compartment, and then look under the dash for any tiny hole where light is visible. Patch or plug every one of them. Use epoxy or “Great Stuff”‘ foam (available at lumber yards and hardware stores) to cover holes. Replace missing rubber grommets on the large (spark plug access) holes. If you leave even the smallest hole, you will pay the price with a jet of 200-degree air blown into your lap-even with the top down.

For a really effective job (especially on MkI Tigers) you should cement closed-cell foam insulation on both the firewall and the floors (over the exhaust pipes). This will cost about $65.00, but it’s worth every dollar in added comfort. You will need a pair of scissors, a can of spray adhesive and two camper’s ground pads (for sleeping on) available from CAMPMOR (send for free catalog: P.O. Box 700-G, Paramus, NJ 07458-0700 www.Campmor.com). Buy the thickest ones. Remove the seats and carpets from your car. It’s easy. Each seat is attached with only two bolts. It’s also entertaining. Wait ’til you see the assortment of junk under your seats! Now lay one of the pads across the transmission housing (side to side), trim to fit and glue in place. Next, go up under the dash and cover every square inch of firewall you can reach. Use of spray adhesives makes it easy. Place large remaining sections on the floor and use scraps to fill in all areas where heat can enter the car. I used every square inch of both pads. Replace carpets and seats and you are ready to go, cooler than ever.

I used to drive my Tiger about 1,000 miles each summer. Now it’s daily transportation even in August due to the great improvement in comfort. Don’t try to cut costs by using ordinary foam insulation. The Campmor pads are superb. You are dealing with a lot of heat and only good material is effective.