by Marc James Small originally published as Truly, Joe Lucas Invented Darkness in the May 1978 RootesReview

If you’re sick and tired of the cost, unreliability, and poor performance of the Lucas alternator fitted to British cars, there is a simple and long-term fix that really solves the problem. An American alternator is easy to fit, readily available, and ruggedly reliable. An American unit will put out about one and a half times the power of the Lucas unit.

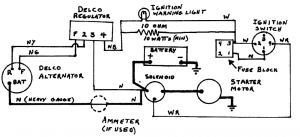

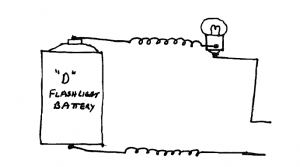

I recommend the Delco models with a separate regulator. They are considerably cheaper, more easily adjusted, and seem to be a lot more reliable than the later internal regulator types. For argument’s sake, let’s just say you’re looking for a 1964 Buick/Olds/Pontiac unit. You want one for cars without air conditioning. You can pick up a Delco alternator in a junkyard for $25 or so, or you can get a new unit from Whitney’s for as little as $44.95 (try stock number 13-1702N). Regulators should run you about $10 or you can get the more elaborate type with screw adjustments for approximately $20. Installation is the only tricky part. First, disconnect the battery and take out the old alternator. Also remove the alternator relay and warning light simulator. Then you have to fabricate a bracket, and that takes a little ingenuity. I haven’t got any hard and fast measurements, as I’m running on a jury rig, but any machine shop should be able to fix you up for a little money. Mount the regulator on the bracket that held the original regulator. Drill some holes and use sheet metal screws, then use a continuity tester–or a piece of wire, battery and light bulb–to insure that both alternator and regulator base are making a good earth. Hold one end on the alternator case and the other on the regulator base and the light should light up. If it doesn’t, then you may want to run ground leads to your alternator or regulator mounting screws. Use the existing black leads for this. Wiring a Series V Alpine is simple. Use the following connections:

| FROM | TO |

|---|---|

| Delco Alternator Terminal BAT | Either the ammeter or solenoid battery terminal-put a spade lug connector on the alternator and use the existing B+ lead (heavy brown wire) |

| Delco Regulator Terminal F | Alternator terminal F-use existing lead (brown with green stripe) |

| Regulator Terminal 2 | Alternator terminal F-use existing lead (brown with yellow stripe). |

| Regulator Terminal 3 | Either the ammeter or solenoid battery terminal-use the existing lead that was connected to Cl of the Lucas alternator relay (brown) |

| Regulator Terminal 4 | Ignition warning light circuit-use the existing lead that was connected to WL on the Lucas alternator warning light simulator (brown with black stripe) |

The warning light circuit is completed by the white wire that was attached to terminal Wl of the Lucas alternator relay. To allow the alternator to charge properly you must install a 10 ohm 10 watt resistor in parallel with the ignition warning light. A resistor may be purchased from a radio and TV repair outlet. One end of the resistor is connected to terminal 4 of the Delco regulator and the other end is connected to terminal J of the fuse block (the terminal with all the white wires). You will probably have to solder a wire to the resistor to bridge the distance. Without this resistor the alternator will not start to charge until the engine is turning 3000 RPM or more.

See the wiring diagram that follows.

Now check to make sure that all remaining disconnected leads won’t touch anything. To be safe, tape them so they are insulated and fastened to the wiring harness. If you are concerned about appearance, cut them off at the harness and tape them.

If you are working with a Series IV or earlier Alpine, it is a little more complex. It will require more extensive rewiring since you will have to contend with a positive ground system. I found a beautifully done Series I with a GM system, in a junkyard north of Baltimore. It can be done.

And that’s it. It is a lot cheaper than a Lucas system and is very reliable. The smallest GM unit made puts out 38 amps and you can move up to 80 amps before you get into high cost. Even with 38 amps you will have power enough for high beams, fast wipers, high blower, and your electric air horns! It is really worthwhile!

[…] Download Image More @ teae.org […]