- This topic has 5 replies, 4 voices, and was last updated December 18, 2011 at 11:18 pm by

David Reina and Donna Koretsky and Donna Koretsky.

-

AuthorPosts

-

-

December 6, 2011 at 5:37 pm #57789

As I disassemble my vehicle piece by piece, I note a wide variety of fasteners, many of them pop rivets of various size or style, plus the occasional slotted screw, phillips screw, or pozidrive screw. While its normally possible to drill or grind off the outward facing rivet head in order to free the underlying part (like threshold trim, scuff plates, convertible top retaining bar, carpet snap retainer ring and the like), I find I’m then faced with a forest of a thousand little nubbins remaining stuck in their little holes.

Any best practice for extracting all those doo-dads? Any practice to avoid (I’m assuming it’s a bad idea to try and drill them out since it will enlarge the holes)? Were any pop rivets used originally or would I be wide to weld up all those holes and make new ones for whatever fastener is the right one when the time for reassembly comes?

-

December 7, 2011 at 4:08 pm #64318

There are pop rivets used. Holding th data plate and vin tag, in the interior heater assembly, the footwell vents for the MK1A/alpine V, convertible top frame, windshield frame holding some of the inside chromed bits, small trim bits around the dash, in a couple spots of the weather stripping and so on. This isn’t a complete list, there’s other odds and ends, but what I recall off the top of my head

-

December 7, 2011 at 8:41 pm #64319

I presume you are well aware of the many cautions about not removing the Vin plate. I just mention that in an abundance of caution. For the record, those rivets are said to be very special, having a unique dome to them and now longer available. That makes them one of the keys to originality. But ultimately it is your car to do with as you wish.

Good luck, Gene

PS: I am belatedly thinking I may have missed the real question. Perhaps it is how to get out the back side of the rivet if it would drop down into a blind cavity. No real answer for that. But, I doubt they have enough substance to make a rattle, at least one anyone could hear with my exhausts!

-

December 8, 2011 at 1:19 am #64320

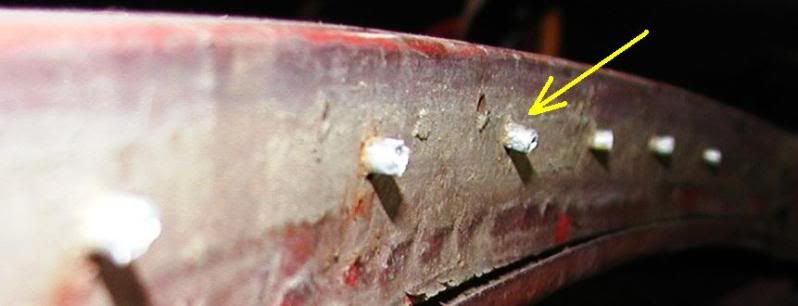

No VIN rivets removed, just a thousand and one of these (below example from removing convertible top retaining strip and fabric at rear deck area). Do you pull them out, push them out, grind off from the back side and pop out, or what? Or do you just mash them out, weld it up, grind, and then drill new holes later?

-

December 8, 2011 at 3:30 am #64321

Were it me, I would just drill the rivet shank showing there in your picture with a 7/64 drill bit (if it were a 1/8th size rivet). The hole in the center is a good guide. Then crush down the thinned metal with pliers to narrow it on all sides. Next try to drive it through with a light hammer tap. May need a narrow, pointed tip type punch (like a leather punch) to finish the job. You could also make one out of an old round shaft screwdriver and a bench grinder. Just make the point long and tappered. (Does anyone remember ice "piks"?!)

But that is just me, I have a habit of finding the hard way to do things.

Gene

-

December 18, 2011 at 11:18 pm #64339

I would not use a pointed tool to push the rivets as this will expand their diameter. Instead take an 1/8 " nail and grind the front blunt. (Or buy a 1/8" punch) Then tap them gently through the holes. Usually when I drill them out with a 1/8′ drill bit I keep drilling until I am through the factory hole. In the picture I would try drifting them gently side to side to loosen them up and then tap them through the holes. I would not make new holes if possible as the factory seemed to use some accurate jigs to make the original holes and you will find them the same from car to car.

Dave Reina

-

-

AuthorPosts

- You must be logged in to reply to this topic.